- Sawing technology

- Planing technology

- Glulam technology

- Company

- News

- Service

- Contacts

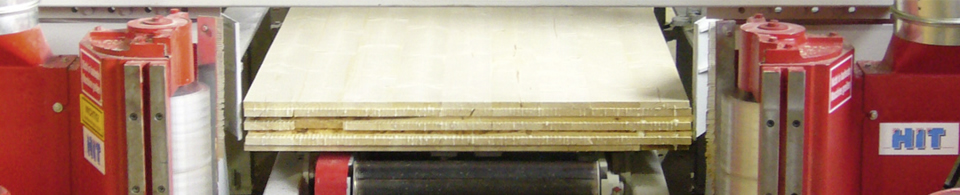

MWith our patented “lignoPRESS” press system, you opt for an elaborate press system, which has already proven itself many times in practice. The glulam production with our press system enables an efficient production with a minimum use of raw materials.

The special benefits of our press system are due to:

With our presses and pertaining beam formation systems, it is also possible to arrange several lamellas next to each other and either produce a glued block or combine several press charges in a single press filling.

Our press system not only includes the actual glulam press, but also the upstream and downstream mechanical equipment.

Our scope of supply includes:

| Press fill width | 320 or 480 mm |

| Press fill height | 65 – 1750 mm |

| Press length | 6 – 24 m |

| Pressing pressure, top | 1 – 2,3 N/mm², depending on the type of press |

| Pressure elements | hydraulic |

With the lignoPRESS glulam press, pressing pressures of 0.8 N/mm ² for timber with relief groove, and 1 N/mm ² for timber without relief groove – as recommended by EN14080 – are reached safely in each configuration. When producing with the lignoPRESS, relief grooves in the lamellas are not required.